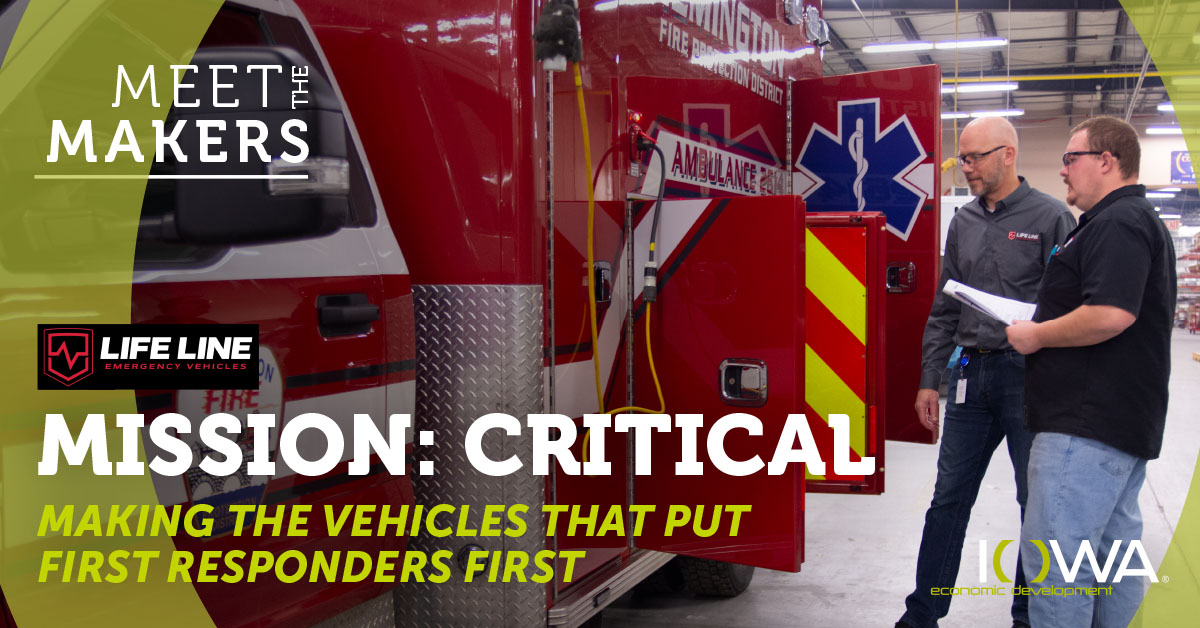

Meet the Makers: Doug Roethler of Life Line Emergency Vehicles

"Quality Saves Lives."

At Life Line Emergency Vehicles, this seemingly simple phrase encapsulates the critically important roles played by the people behind this Sumner, Iowa-based manufacturer. For more than 35 years, communities across the country have entrusted their emergency vehicle needs to Life Line – an award-winning, employee-owned company whose team understands that reliability, safety and durability are of the utmost importance when seconds count.

The company’s recent recognition in Washington, D.C., as the 2022 National Employee-Owned Company of the Year was based on one major factor: dedication. From its dedication to employees and commitment to community, this small manufacturing company is living up to Sumner’s big motto, “The City with a Future.” Continually reinventing itself to remain globally competitive, Life Line is further proving that its investment in people today will ensure a strong future for them tomorrow.

Doug Roethler, Life Line’s director of operations, oversees engineering, manufacturing, purchasing, quality, safety, HR and maintenance for the company. A proud Iowa native, Doug gave us a behind-the-scenes look at how Life Line Emergency Vehicles became a trusted partner for first responders across the nation and how the company’s investments in new technology have further cemented Life Line as a major player in the manufacturing field.

Doug Roethler, Life Line’s director of operations, oversees engineering, manufacturing, purchasing, quality, safety, HR and maintenance for the company. A proud Iowa native, Doug gave us a behind-the-scenes look at how Life Line Emergency Vehicles became a trusted partner for first responders across the nation and how the company’s investments in new technology have further cemented Life Line as a major player in the manufacturing field.

Q: Where did you grow up, and what led you to working in Iowa/at Life Line Emergency Vehicles? How did you choose this career?

Doug Roethler (DR): I grew up in a rural community in northeast Iowa near Riceville. While finishing up my education at the University of Northern Iowa, I worked as a machine operator, project manager and production manager for a local manufacturer. I spent a little more than 20 years with that company, then moved on to serve as director of operations for an engineering company specializing in custom machine builds. While I was there, I realized my talents could be put to better use, which is what led me to Life Line. I’ve been here for a couple of years, and it’s been a really rewarding experience.

Q: Tell us about what Life Line Emergency Vehicles does and the kinds of clients/industries you serve. What is the company best known for?

DR: Life Line produces high-end, custom ambulances sold through a network of distributors that serve a variety of municipalities – from large metropolitan areas to small communities. Over the years, we’ve built a reputation for superior quality, thanks largely to specialized manufacturing processes that ensure our vehicles meet our end customers’ exacting standards. From the aluminum exteriors down to the circuit boards, we take special care to make sure our ambulances put EMTs in the best position possible to serve their communities.

DR: Life Line produces high-end, custom ambulances sold through a network of distributors that serve a variety of municipalities – from large metropolitan areas to small communities. Over the years, we’ve built a reputation for superior quality, thanks largely to specialized manufacturing processes that ensure our vehicles meet our end customers’ exacting standards. From the aluminum exteriors down to the circuit boards, we take special care to make sure our ambulances put EMTs in the best position possible to serve their communities.

Q: How has your role at Life Line evolved since you began? Similarly, how has the company evolved how it operates – new technological advances, new manufacturing processes, etc.?

DR: My role is the same since I started two years ago, but our processes and how we integrate new technologies have improved our business for the better. We’ve invested in advanced computer numerical control (CNC) bending equipment to support R&D projects that will increase efficiencies while reducing repetitive motion injuries. We are also investing in robotics to aid in similar efficiency gains. These investments will allow us to continue developing our team’s skillset through opportunities to gain experience with new equipment and new processes.

Q: What appeals to you about living and working in Iowa?

DR: I’ve lived and worked in Iowa my entire life. I love to travel, but at the end of the day, Iowa’s low key, spacious and beautiful environment is what I prefer. While I was with my first job, my family and I were close to relocating to Birmingham (Alabama) for another opportunity within the company. We sold our house and set plans in motion, but at the last minute, we had second thoughts about leaving our networks and extended family. Plus, the quality of life here was tough to beat, so we decided to stay. A couple of years later, I landed at Life Line, so I’d say the decision to stick around worked out well.

Q: How does what the state offers to businesses factor in when considering the opportunities and success you’ve achieved?

DR: Without the assistance of grants received from the Iowa Economic Development Authority, it may not have been possible to invest in the CNC bending equipment and robotics. In my opinion, the state is very proactive about helping manufacturers and other businesses achieve their goals and so much more.

the state is very proactive about helping manufacturers and other businesses achieve their goals and so much more.

Q: What’s next on the horizon for Life Line?

DR: We’re excited to introduce even more innovative equipment and ideas into our manufacturing and administrative processes. A few of our long-tenured colleagues recently retired, and their institutional knowledge is irreplaceable. But given today’s ultracompetitive labor market, this shift also opens the door to new and improved solutions to fill that gap and further develop our existing workforce, which is key to continuing our growth.